Heat Transfer Vinyl 4U, your #1 Craft & Hobby Garment Decorating & Decal Store! From Siser HTV to Printing Equipment & Heat Presses!

Your Trusted Source for DTF, heat transfers vinyl HTV, Craft Vinyl heat transfers machines, and Papers, Heat Presses, Printing Equipment and supplies, Sublimation, and More!

Since 2010, we're known for fast shipping and turnaround time with superb customer service.

We also provide Custom DTF Transfer, HTV Prints and Decals for any surface including all types of fabrics.

Easy and Professional Heat Transfer Vinyl

Heat transfer vinyl (HTV) is a popular method for creating custom t-shirts and other garments. Using a heat press, heat transfer vinyl sheets are applied to the fabric, resulting in a long-lasting and durable design. With a wide range of colors and options available, including glitter and puff options, there are endless possibilities for creating unique designs.

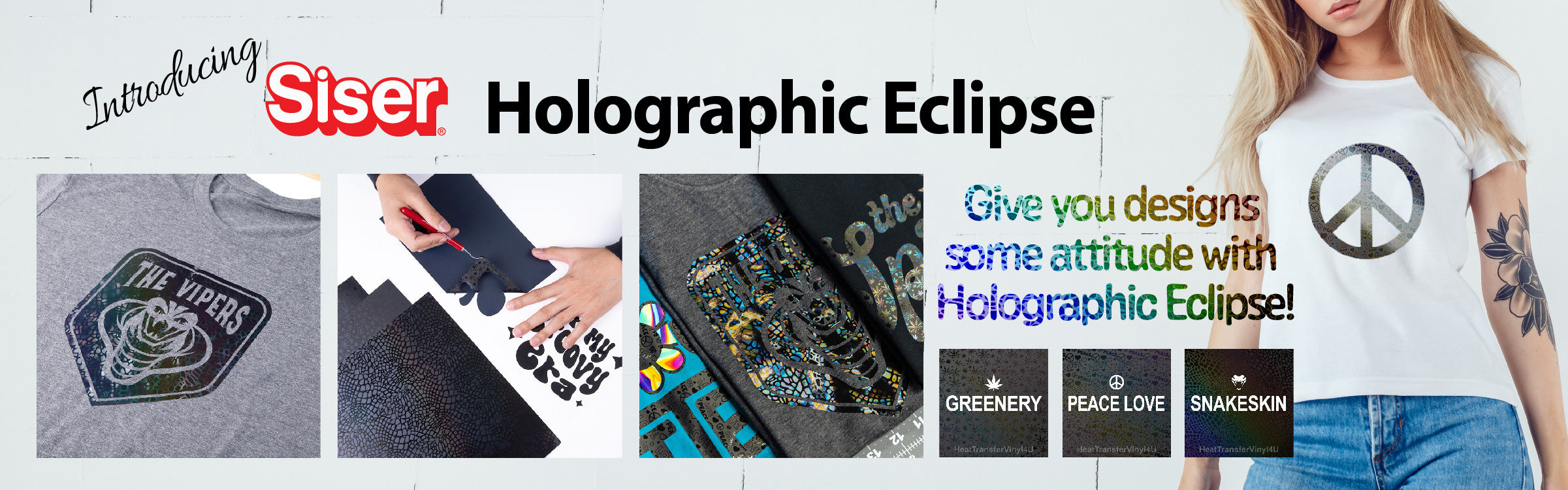

Siser Easyweed is a popular brand of heat transfer vinyl, known for its easy application and high-quality results. With vinyl cutters and sublimation machines available, it's easy to create custom vinyl transfers in-house. In addition to t-shirts, heat transfer vinyl can also be used on hats, bags, and other accessories.

Easysubli is another type of heat transfer vinyl, designed specifically for use with sublimation printers. This allows for the creation of full-color transfers with vibrant colors and sharp details. Whether you're a small business owner or a hobbyist, heat transfer vinyl is an affordable and easy way to create custom apparel and accessories for your shop or personal use.